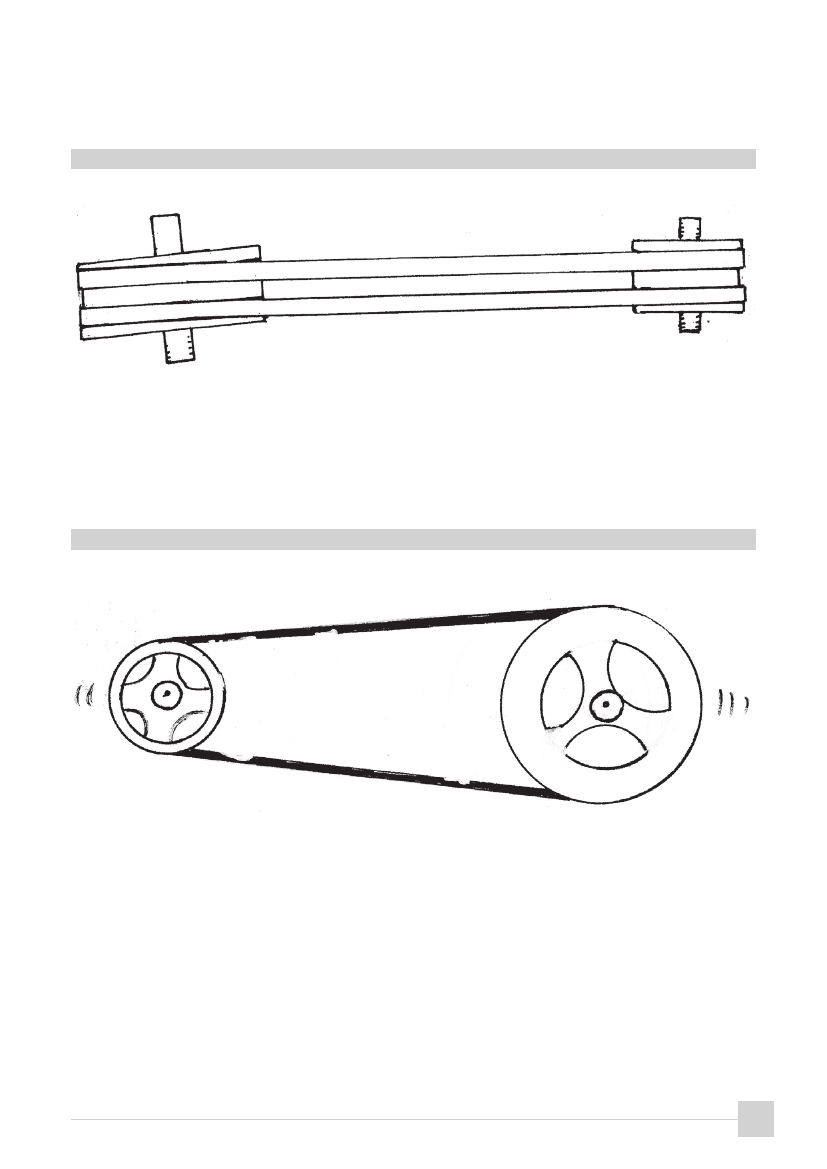

Drive system

A special drive system is available only if the turbine speed does not match the generator speed. Then

flat or V belt and pulley systems are used.

Misaligned Pulleys

Village technicians should have an idea of the tension level of such a belt. If the belt sags too much it

should be tightened up to the original level. if the belt tension. be careful to maintain pulley alignment.

The possible misalignments are shown in the picture above.

Cracked Belt

As soon as the turbine is stopped after a long period of running, the pulley and belt have high temperatures

if they are under or over the required tension level. Thus, familiarising yourself with the belt and pulley

temperatures will enable you to identify problems with the tension levels. Further the belt should be

inspected for cracks and wear and tear once a month.

Such a belt system should not be exposed to water and grease, etc. Whenever a new belt is replaced all

the belts should be replaced at once. Do not use a mix of old belts and new belts at the same time.

With the belt drive system there is an additional bearing set also. Then that bearing should be maintained

by greasing on time.

17